Microtronic - 可焊性測試 (Solderability Tests)

LTB210 可焊性測試儀 - 全自動化電腦控制

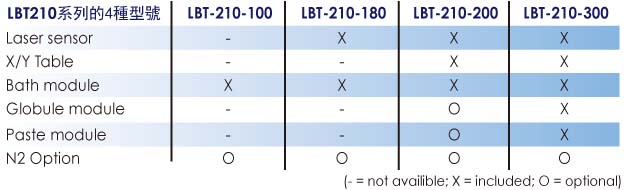

Microtronic 提供範圍廣泛的產品,包括電子質量控制,研發,維修和製造行業先進的系統。其中,LBT-210 自動和 PC 控制焊性測試儀是最流行的。旨在檢查電子焊點的完整性和質量,這種尖端的系統滿足電子製造行業目前的挑戰。通過焊浴或熔球或焊接:可以使用兩種經典方法進行可焊性測試。它也提供了一種新的方法,以幫助改善生產,使用焊膏和溫度曲線。用這種新的方法,一個組件被放置在印刷焊膏,並通過在生產中使用的相同的溫度分佈加熱。在加熱週期內的所有力參數和值監測和分析。這是模擬和資格的在線生產焊料爐的焊料輪廓與不同焊膏和部件一起的唯一已知方法。

測試方法和選項 :

• 焊浴測試具有自動刮刀與糟粕斌

• 錫球測試與 1,2,3 & 4mm 和鏟斗二手焊球

• 焊膏測試用基板,焊膏和組件

• 多針自動測試

• 在氧氣中的自動測試

• 粘著性測試(可選項)

• 全中央數據庫

• 預熱

特性 :

• 動態範圍

• 自動放大

• 振動阻尼設計

• 無刷直流伺服電機

• 定位:大于 5um

• Bath 表面位置由接觸式激光傳感器確定

• 可捕獲測量的視頻

• 數據保存在 SQL 數據庫的統計分析

• 在 CSV 和測試文件中的數據導出

• 曲線作為圖像文件導出

• E-stop,CE 認証

• 軟件採用德語,英語,法語(也可選其它語言)

應用 :

• 元器件測試

• 基板測試

• 潤濕力測試

• 助焊劑特性測試

• 粘合劑特性測試

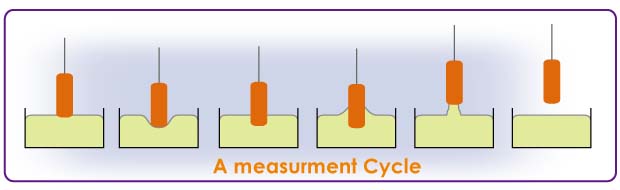

Storing Modules

Inserting a Module

Test with Globule

Test with Solder Bath

Test with Solder Paste

Easy to use software

Fan to cool the modules

.png)

.png)

.png)